Materials analysis

Our materials analysis includes mechanical and physical material analyses, such as structure, texture and microstructure analyses, hardness tests or porosity measurements. These form the basis for testing and optimising the mechanical/physical properties of materials as well as for optimising manufacturing processes and damage analysis.

Materials

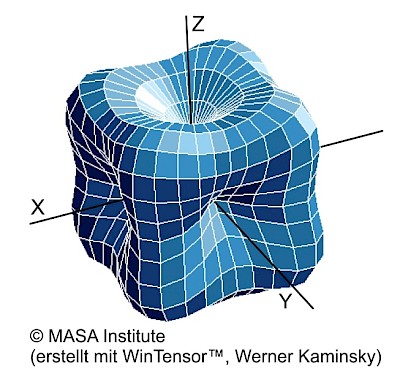

The physical and mechanical properties of both materials and materials from the geosciences are usually anisotropic, i.e. directionally dependent. These properties result from the internal structure, size and orientation of the crystallites, as well as the grain boundary properties and intrinsic stresses of the material. The quantitative determination of these parameters is therefore very important for many developments in technology, mechanical engineering, the optimisation of materials and processes in product development and the manufacture of many materials. These methods are also very important in damage analysis. For geoscientific research, this analysis forms the basis for the reconstruction of geological deformation processes, as well as for rock mechanical analyses. Our analyses are aimed at both applied issues (materials testing) and basic research.

Our methods

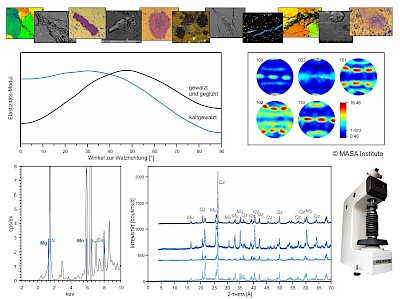

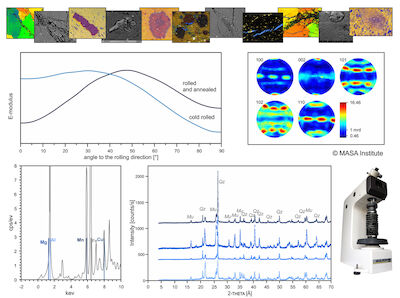

We offer various methods at our institute, which can also be combined if required. This allows us to analyse samples either as a whole (global) or spatially resolved (local). For the global analysis of materials, we use diffraction methods, which are carried out using X-ray, synchrotron or neutron diffraction, depending on the problem. Here it is possible to carry out both powder and texture analyses on a wide range of materials. We also offer spatially resolved texture, microstructure and metallography analyses using scanning electron microscopy, Laue cameras and optical microscopy. Hardness tests can also be carried out on various materials. On request, we can also analyse alloys and multiphase materials using non-destructive methods. We work with you to develop an optimum analysis strategy for every problem.

Diffraction

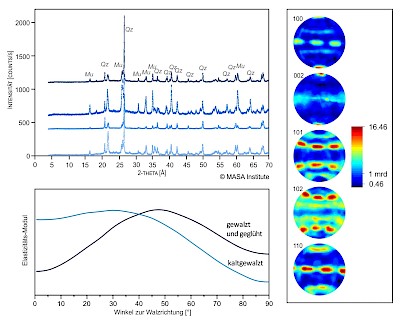

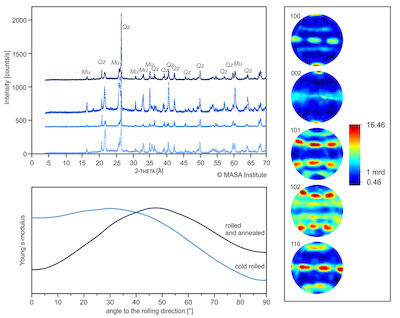

Our laboratory has X-ray diffractometers for both powder and texture analyses. Using powder diffractometry, we offer qualitative (search/match) and quantitative phase analyses (Rietveld analyses). On the basis of texture analyses anisotropic macroscopic material properties such as Modulus of elasticity, thermal dilatation, magnetic properties, plastic material behaviour during Forming (r-value) or the determination of the material condition (e.g. complete or partial recrystallisation). We also carry out stress analyses for you (residual stress, material stresses under mechanical load), experiments under uniaxial pressure and grain size analyses, as well as crystallite size distribution analyses. These methods can also be combined with spatially resolved methods. If required, i.e. depending on the material properties and the issue at hand, we also carry out powder and texture diffractometry externally at synchrotron or neutron sources. We also offer determination of single crystal orientations and quality determination of single crystals in polycrystalline materials using a Laue camera.

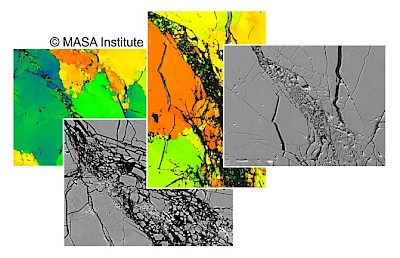

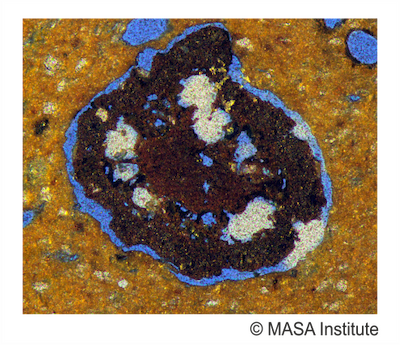

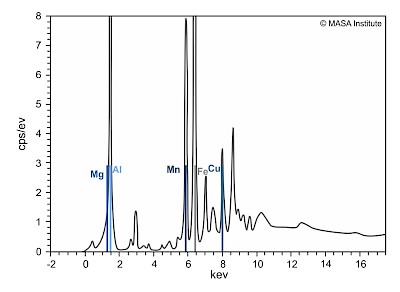

Scanning electron microscopy

Our analysis using scanning electron microscopy includes microstructural analyses and metallography using backscatter and secondary electron images, as well as texture analyses using EBSD (Electron Backscatter Diffraction). The backscatter images can be analysed quantitatively (e.g. particle analyses, grain sizes, grain boundary orientations, porosity and crack distributions in 2D) on request. We also offer analyses of mineral and crystal iterations. For this purpose, element distributions in profiles or grid analyses, e.g. for damage analysis, can be analysed using energy-dispersive X-ray analysis (EDX). In addition to global texture analyses, EBSD can be used to carry out locally resolved crystal orientations with a resolution of 500 nm.

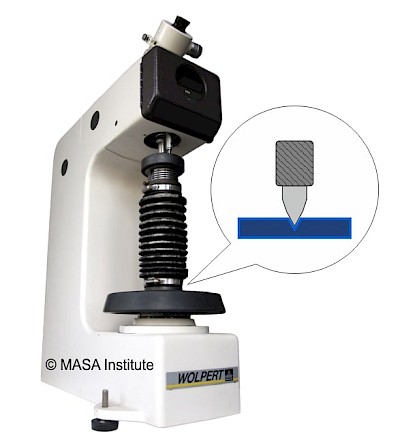

Hardness tests

For hardness tests, we use a Vickers Wolpert Testor 4021 micro hardness testing machine, which is equipped with a test probe to measure individual structural components in the HV 0.2 to 10 kp hardness scale, i.e. in the force range of 1.96 - 98.07 N. We naturally offer this material test individually or in combination with other analyses.

Porosimetry/pore space determination

Porosity is an important parameter for the storage capacity or filter properties of a material. This includes materials such as ceramics, plastics, metallic and other foamed materials, building materials or even natural rocks, which are used as gas reservoirs, for example.

We offer you various methods for different porosimetry issues:

- Mercury porosimetry: pore measuring range: 3.6 nm - 116 µm, size distribution of the pore space, density calculations

- Computed tomography (also nCT): quantitative imaging method in 3D, pore space, pore pathways, partial phase differences

- Optical pore space determination: quantitative image data evaluation using thin section microscopy

- Water porosimetry: determination of porosity (%), density calculations

We develop an optimal analysis strategy for you according to your specific problem(s).

Alloy determination

At our institute, we also offer spatially resolved X-ray fluorescence analyses (XRF/XRF), which are very well suited to checking the chemical composition of alloys of metallic materials. This material testing can be carried out at individual points, in line profiles or at grid points over surfaces. If required, these analyses can also be combined with further metallography.

Optical microstructure analysis

At our institute, we carry out optical microstructure analyses using either transmitted light microscopy (geomaterials, ceramics, etc.) or reflected light microscopy (metallography). With transmitted light microscopy, the analytical resolution is up to 0.2 μm, while resolutions of up to 1.6 μm are possible with reflected light microscopy. On request, quantitative analyses of the microstructure can also be carried out using image data evaluation for both methods. If required, these analyses can also be supplemented with other methods from our materials testing department.

Applications of materials analysis

- Optimisation of products and manufacturing processes (forming, recrystallisation)

- Damage analysis

- Determination and optimisation of the mechanical and physical properties of (geo)materials

- Characterisation of plastic and fracture deformation processes

- (Mineral) phase analyses of raw materials and materials